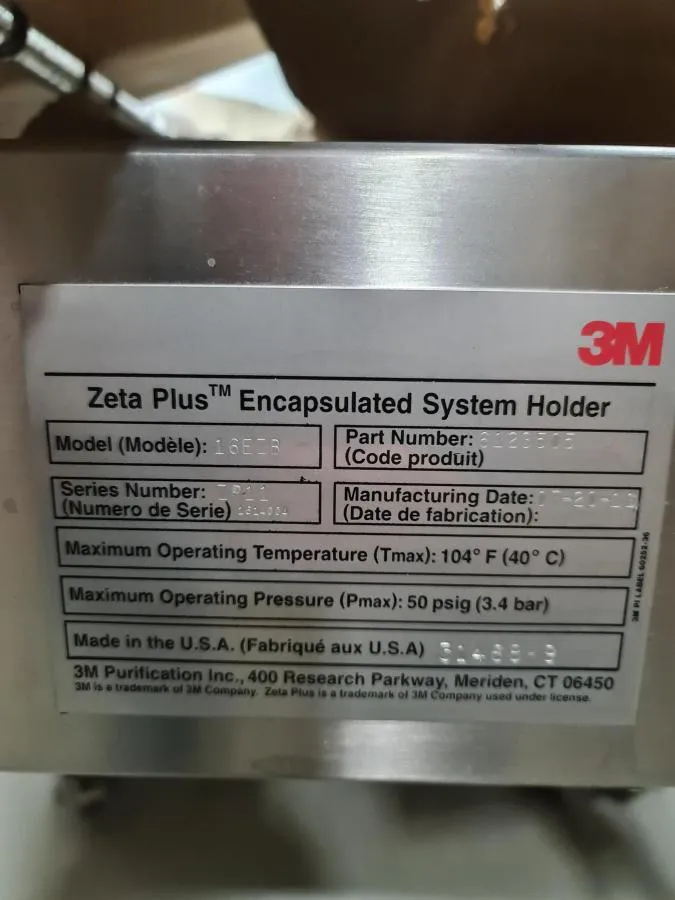

3M Zeta FILTRATION Plus Encapsulated EZP Plate-and-Frame 16EZB MPN 6123505

- Make 3M

- Hertz 50Hz/60Hz

- Model 16EZ8

- Serial ZP11-1814004

- Weight 100

- Voltage 120V/220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

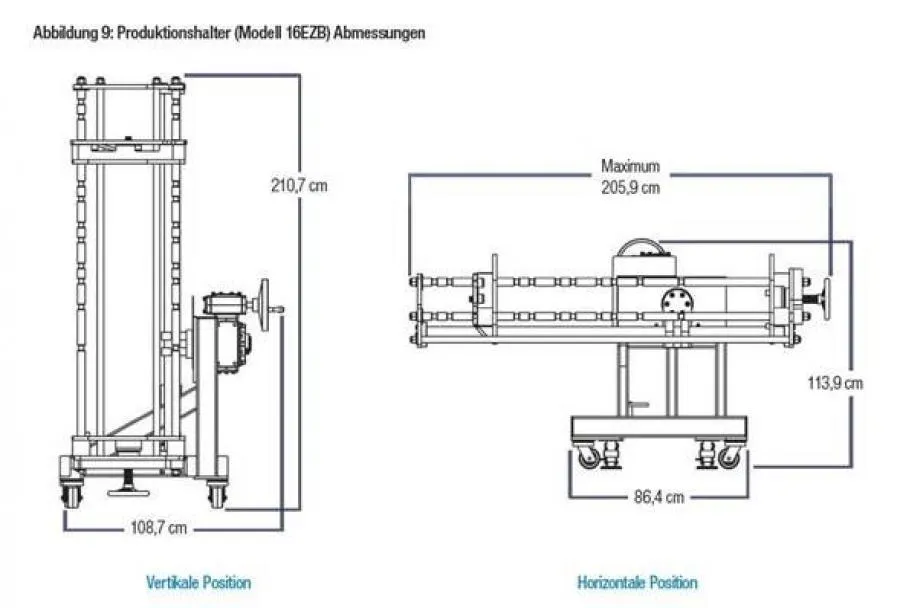

- Dimensions 250×100×125 in

- Shipping Type Freight

- Item Condition Pre-owned

- Manufacturing Date 07-20-11

3M™ Zeta Plus™ EZP Series System Holder 16EZB, 6123505

Product was removed from a working environment.

- Ergonomic design enables loading and unloading of filter capsules at waist height, resulting in minimal fluid spills when handling spent capsules (production and multi-round models only)

- Vertical flow path allows effective utilization of the filter media

- Vertical orientation saves floor space

- Available translucent plastic shell allows detection of the liquid level for real time monitoring of the filtration process

- Solid core design with fully encapsulated shell eliminates the need for a stainless steel housing and the post-filtration cleaning and validation steps

3M™ Encapsulated Production Systems can be pivoted to the horizontal position for ergonomic loading and unloading at waist height and to the vertical position for filtration. This means operators do not have to lift capsules above their heads and risk exposure to fluid spills when handling used capsules and drastically reduce the time it takes to change out filter cartridges.

Vertical flow path allows effective utilization of the filter media

We preserved the vertical flow path design in our 3M™ Encapsulated System that has been proven effective for depth filtration in traditional cartridge and stainless steel housing systems. This design helps to provide consistent performance during the transition from traditional cartridges to single—use systems.When faced with the challenges of filtration for the bioprocessing industry, where upstream cell culture clarification or downstream impurity removal is required, the 3M™ Encapsulated Production Systems meet this challenge and with an ergonomic, space—saving assembly. The 3M Encapsulated Systems consist of three configurations; a pilot system that is ideal for scale—up studies, and two production systems that are designed for production scale bio-manufacturing.

Either single stage or two—stage depth filtration can be performed within the same Encapsulated Production System. The Encapsulated Production Systems have a built—in torque limiter that will signal that the assembly is properly sealed. Our Encapsulated systems for production scale bio manufacturing go the full measure of utility with ergonomically designed hardware that can be pivoted between horizontal and vertical positions. This innovative feature allows for fast and convenient loading and unloading at waist height, small footprint during filtration and storage, minimal fluid spills during unloading, and effective utilization of the filter media.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”